Laser welding is an advanced method of joining materials using a laser source. Lasers have evolved over time, starting with gas lasers such as CO2, which operate continuously and usually have higher power.

Hydraulic simulation software helps you create custom integrated manifolds. The product incorporates the schematic layout and pricing tool from previous versions with the addition of a 3D layout tool.

Image Source: Google

Later came solid-state lasers such as Nd:YAG, which can operate in both pulse and continuous modes. More recently, fiber optic lasers have been developed to enable high power welding in either pulsed or continuous modes with a greater range of flexibility.

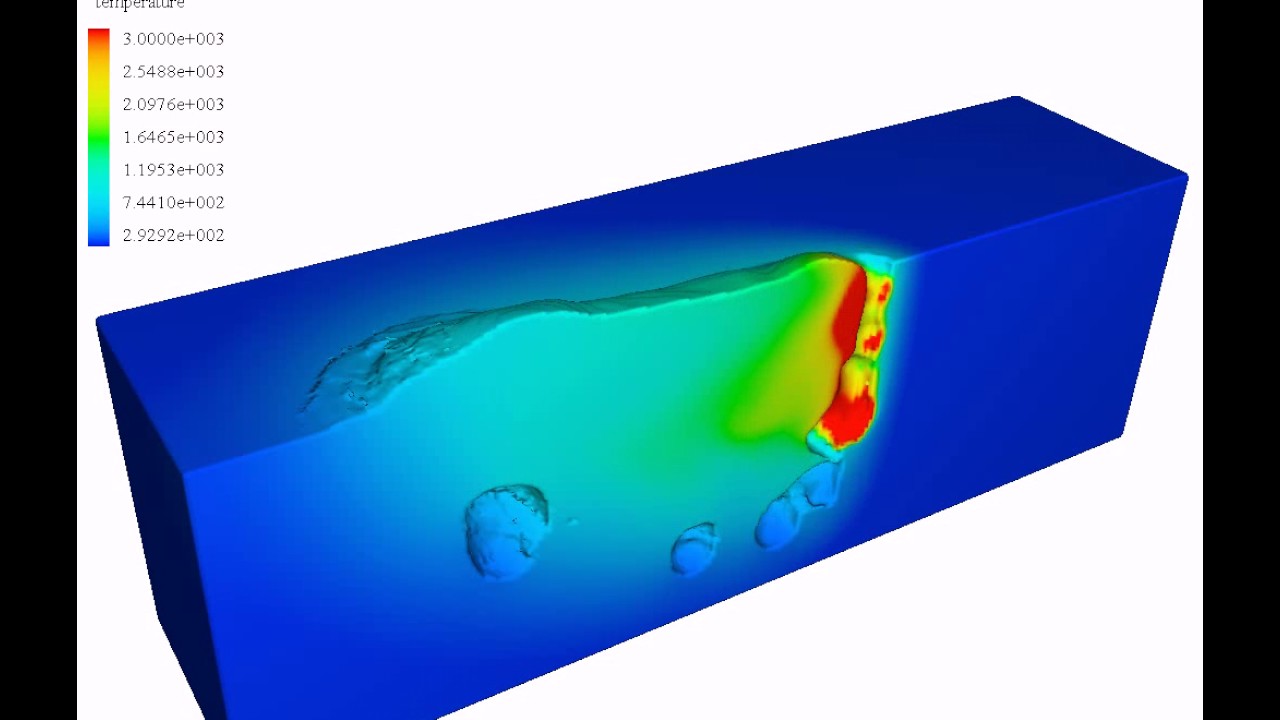

How to optimize Laser Welding? Simulation!

Identifying the sources of these defects and optimizing process parameters to minimize them can be challenging in an experimental space, as this requires many physical trials with accompanying destructive testing methods.

There are few tools available for doing micro- and meso-scale analysis of melt pool dynamics which require high fidelity models including fluid flow, heat transfer, phase change, and laser-material interactions as they relate to laser setting such as power, distribution, speed, and scan paths, as well as additional physics such as laser reflections and shield gas effects.

FLOW-3D weld has been uniquely designed to accurately model the melt pool dynamics at the micro and meso scales which gives insights into process dynamics which are difficult, if not impossible, to capture with conventional experimentation.